Fully participation

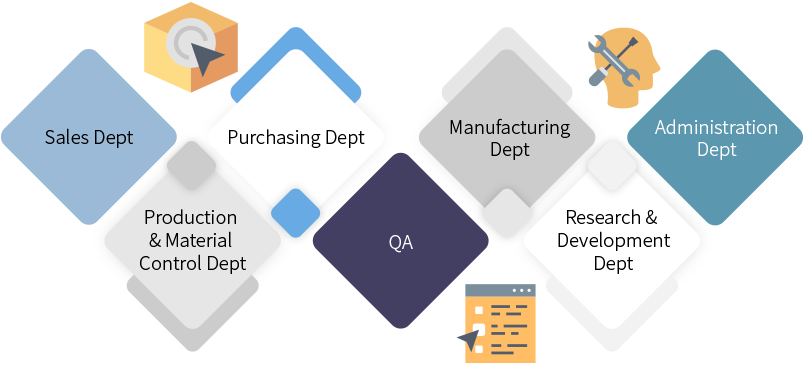

Customer demand oriented:Sales/Research and Development/Production & Material Control/Manufacturing/Quality assurance/Purchasing department.

Fully throughout

Customer demand passthrough from all departments to all stages

Development stage→Trial run stage→Mass product stage→Marketing feedback stage.

Customer demand oriented:Sales/Research and Development/Production & Material Control/Manufacturing/Quality assurance/Purchasing department.

Fully throughout

Customer demand passthrough from all departments to all stages

Development stage→Trial run stage→Mass product stage→Marketing feedback stage.

To ensure the lowest production variability

Use tools-acknowledge

Use tools-acknowledge  Related methods-formulate

Related methods-formulate  Record file-storage

Record file-storage  Work station-clear

Work station-clear  Responsible personnel-dedicated

Responsible personnel-dedicated  Corresponding documents-follow

Corresponding documents-follow  Exception handling-define

Exception handling-define Fully control on the production side.

Continuious to observe the achievement of indicators at customer side.

Plan for the process of implementing measurement, supervision, analysis and improvement to ensure the quality records and quality activities related data that occur during the production process,these data can be executed various analysis to discover the potential problems and trends, using data analysis to prevent issue occur from production line to improve customer satisfaction.

In order to achieve the goal of perfection, the following reaction procedures has clearly defined:

From the raw material to finished goods, Hamburg has executing the Total Quality Control system to ensure

each process are all under control

Continuious to observe the achievement of indicators at customer side.

Plan for the process of implementing measurement, supervision, analysis and improvement to ensure the quality records and quality activities related data that occur during the production process,these data can be executed various analysis to discover the potential problems and trends, using data analysis to prevent issue occur from production line to improve customer satisfaction.

In order to achieve the goal of perfection, the following reaction procedures has clearly defined:

- Implementation requirements and regulations for incoming material inspection, process inspection, and finished product inspection procedures

- Internal quality audit implementation procedures

- The essentials of applying to quality control method to statistical techniques

- Corrective and preventive action procedures

- Customer satisfaction evaluation procedures

- Customer complaint handling procedures

- Non-conforming product handling procedures

- Customer return processing procedures

- Continuous improvement control procedures

- Special use(waive) management procedures

From the raw material to finished goods, Hamburg has executing the Total Quality Control system to ensure

each process are all under control